Features

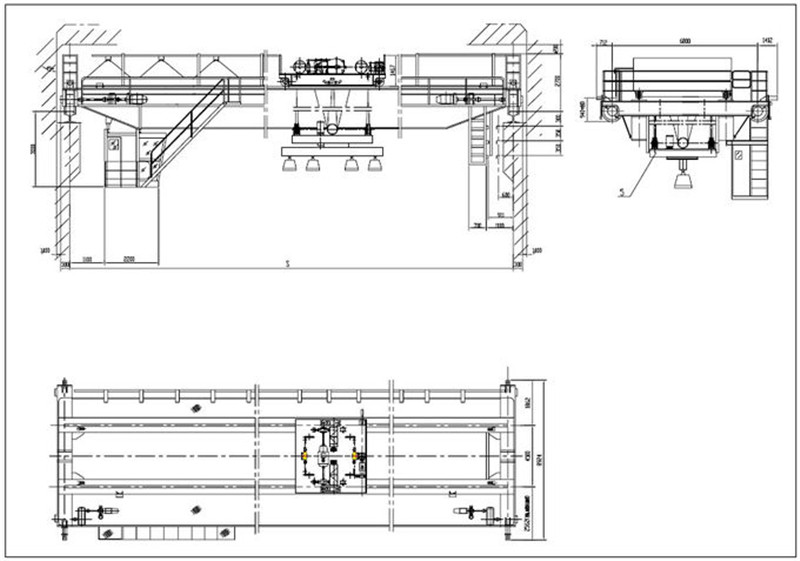

1. It is used for lifting 5t~50t stuff; 2. It has beautiful box-typed welded main girders. Computer-optimized design for main girders with good performance and lightweight; 3. Compact structure, lightweight and high lifting height; 4. The Max. span reaches 32 meters; 5. It's widely used in workshops, metallurgy, warehouses and assembly shops etc.Electric System

1. Power supply through step less slide lines; 2. Lifting mechanisms and traveling mechanisms are mutually independent and could travel at the same time; 3. Control panel protection degree is IP54; 4. Reasonable components installation, convenient for check and maintenance; 5. Electric cable is suspended in cable saddle, stationary cable trolley which slides on a galvanized C-type steel;Technical parameters

| Lifting Capacity(t) | Span (m) | lifting height (m) | working duty | lifting speed (m/min) | crane traveling speed (m/min) | trolley traveling speed (m/min) | total power |

| 15 | 22.5~31.5 | 16 | A6 | 13.2 | 36.7 | 101.4 | 63 |

| A7 | 15.8 | 36.6 | 103.9 | 79.5 | |||

| 20 | 16 | A6 | 12.6 | 36.2 | 89 | 71 | |

| 15 | A7 | 15.8 | 42.8 | 103.9 | 94.5 | ||

| 32 | 15 | A6 | 12.5 | 37 | 87.3 | 111.3 | |

| 16 | A7 | 15.1 | 43.3 | 104.3 | 135.5 | ||

| 40 | 16 | A6 | 11.7 | 37.5 | 87.3 | 128.5 | |

| A7 | 15.3 | 43.2 | 113.9 | 173 |

Mechanism

1. box-type shaped by wielding; 2. High-quality carbon steel Q235B and Q345B; 3. the girder connected by high strength screws; 4. Welding seams are tested by X-ray and ultrasound; 5. Forged wheels; 6. Compact structure, small volume and lightweight trolley; 7. The lifting mechanism is open type winch trolley; 8. Compact reducer motor drive, step-less control, hardened gears and safety disc brake; 9. Good operation performance, step-less speed regulating and running smoothly; 10. Main girders Shot blasting sa2.5 after welding to release internal stresses; 11. Painting high-quality epoxy zinc-rich primer, and the thickness of oil film is 140μm;

Safety Protection Devices

Overload limiter, limit switch (lifting and traveling), interlocking protection devices, buffer, track sweep plate, shield, bus bar protection board, anti-collision device, main disconnecting switch, emergency stop system and motor overload protection.| Lifting Capacity(t) | Span (m) | lifting height (m) | working duty | lifting speed (m/min) | crane traveling speed (m/min) | trolley traveling speed (m/min) | total power |

| 15 | 22.5~31.5 | 16 | A6 | 13.2 | 36.7 | 101.4 | 63 |

| A7 | 15.8 | 36.6 | 103.9 | 79.5 | |||

| 20 | 16 | A6 | 12.6 | 36.2 | 89 | 71 | |

| 15 | A7 | 15.8 | 42.8 | 103.9 | 94.5 | ||

| 32 | 15 | A6 | 12.5 | 37 | 87.3 | 111.3 | |

| 16 | A7 | 15.1 | 43.3 | 104.3 | 135.5 | ||

| 40 | 16 | A6 | 11.7 | 37.5 | 87.3 | 128.5 | |

| A7 | 15.3 | 43.2 | 113.9 | 173 |