overview

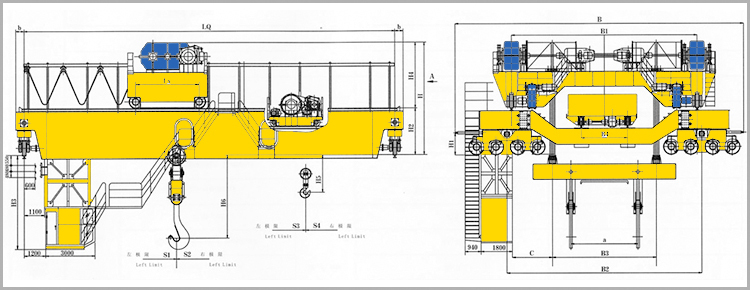

Casting cranes are the main equipment in the steel making continuous casting process, mainly used for lifting and transporting liquid ladles.It is used for lifting molten iron injection mixed iron furnaces, steel making furnaces and lifting molten steel injection continuous ingot casting equipment or steel ingot molds. The main hook lifts the bucket, and the secondary hook performs auxiliary work such as flipping the bucket. The casting crane designed and manufactured by our company has the characteristics of novel structure, safety and reliability, economic durability and simple maintenance. In addition, our casting crane has a rota-table spreader; Gantry hook pitch variable; Functions such as weighing and displaying of loads are optional for customersEnvironmental conditions

1.The temperature of working environment is -10~60Oc. 2.The relative humidity is no more than 50% when the temperature is +40OcTechnological parameter

| capacity | 5 | 10 | 16/3.2 | 20/5T | 32/5T | 50/10t | 74/20t | |

| span | 5-35.5m | |||||||

| max.lifting height | 6-30m | |||||||

| mian hook lifting | 10.7 | 9.8 | 7.8 | 7.8 | 6.1 | |||

| Speed | second hook lifting | 15.5 | 10.4 | 14.6 | 15.5 | 15.5 | 10.4 | 9.7 |

| trolley speed | 37.2 | 43.5 | 44.6 | 44.6 | 42.4 | 39.3 | 33.8 | |

| crane speed | 93.7 | 93.7 | 89 | 89 | 89 | 76.6 | 67.3 | |

| main lifting | 15 | 22 | 37 | 45 | 55 | 75 | 90 | |

| motor | second lifting | 11 | 15 | 15 | 22 | 37 | ||

| trolley traveling | 1.5 | 2.2 | 3.7 | 3.7 | 7.5 | 11 | 15 | |

| crane traveling | 7.5X2 | 7.5X2 | 11x2 | 11x2 | 2x11 | 15X2 | 22x2 | |

| Steel rail | Trolley | |||||||

| Crane | ||||||||

| power source | ||||||||