Painting

The STS shall use the zinc epoxy painting system. They paint could guarantee a minimum paint life of minimum 5 years against cracks, rusty, peeling and discolourtion. Every surface of metal have surface cleaning according to standard sis st3 or sa2.5. Then they are painted with one coat of epoxy zinc rich primer with dry film thickness of 15 microns. The primer coat - shall be painted with one coat epoxy zinc rich primer, dry film thickness of 70 microns. The intermediate paint shall be painted with one coat epoxy micaceous iron oxide, dry film thickness of 100 microns.The finish coat shall be painted with two coats, poly urethane, the thickness of each coat is 50 microns.the total dry film thickness shall be not less than 285 microns to Crane Management System (CMS) The crane management system shall be full computerised operation, complete with sensors and transducers which shall be installed permanently on each crane and work in conjunction with the plc. provide with the monitor to monitoring diagnostics of crane, telling the data collection on the crane’s operating system, operated jointly with the device at least including the electrical power supply device, motor controls, operator control, motor, gear reducers and etc., such programme shall be flexible enough to change or modify by the operator at later stage. Having following function. 1.Condition Monitoring 2.Fault Diagnosis 3.Store the record and display system of the STS 4.Preventive maintenanceDescription

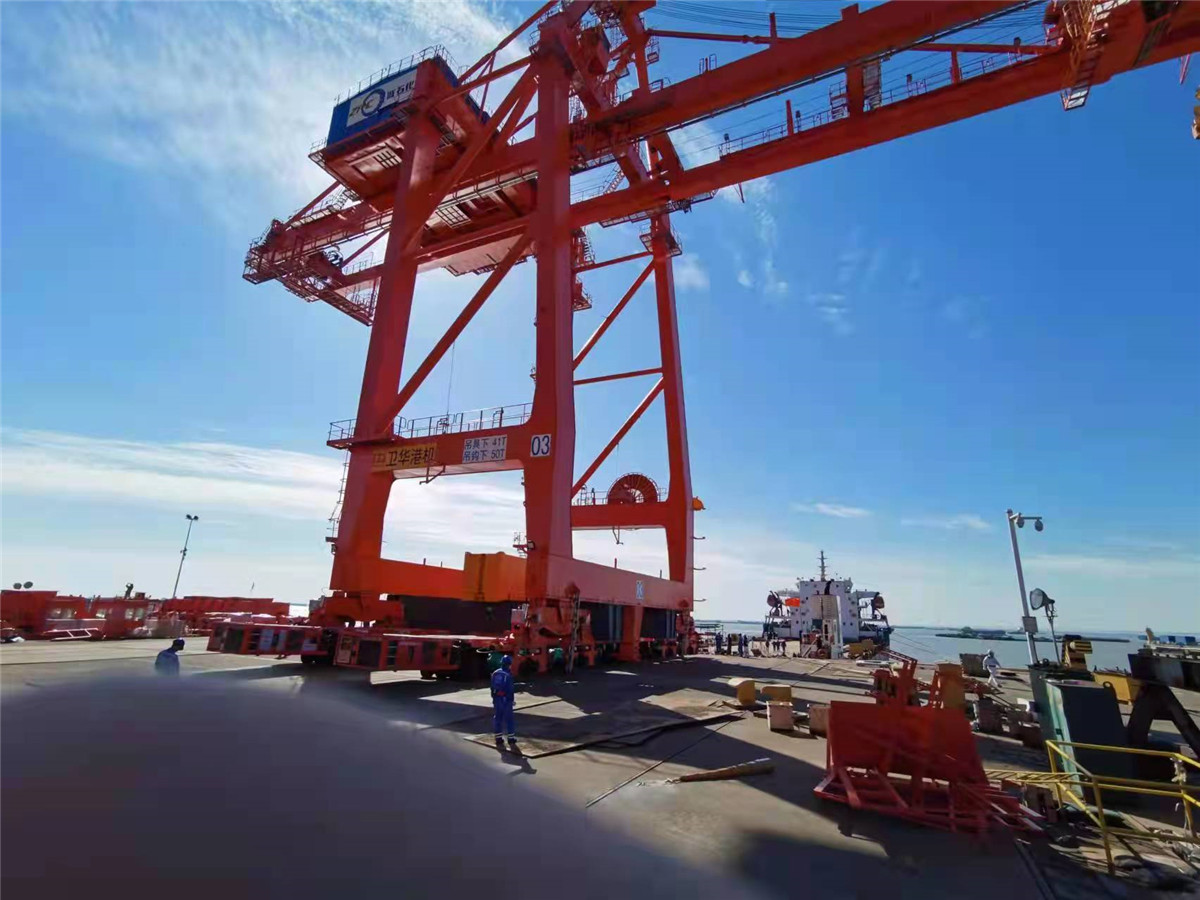

Ship to shore container cranes (abbreviation STS), mainly composed of luffing mechanism, lifting mechanism,crane traveling mechanism, trolley traveling mechanism, machinery room, spreader, electrical equipment and other necessary safety and auxiliary equipment. Depending on the type of trolley, the model is divided into traction, semi-traction, self-propelled, with the adoption of PLC control systems and CMMS automatic-fault monitoring and diagnostic functions, there is sufficient communication and lighting.Features of STS

1.Handle 20ft,40ft,45ft container. 2. All mechanism are interlock to ensure operation safety; 3.Wind cable,electric hydraulic rail clamp,anchor, lighting rod etc.as safety device. 4. PLC control, AC frequency speed control, stable and reliable running; 5. Diesel engine power ; 6. Adequate protection devices, communication and lighting system. 7.Crane Monitoring Management system (CMS) to monitor each mechanism working condition and fault diagnose;

Crane Management System (CMS)

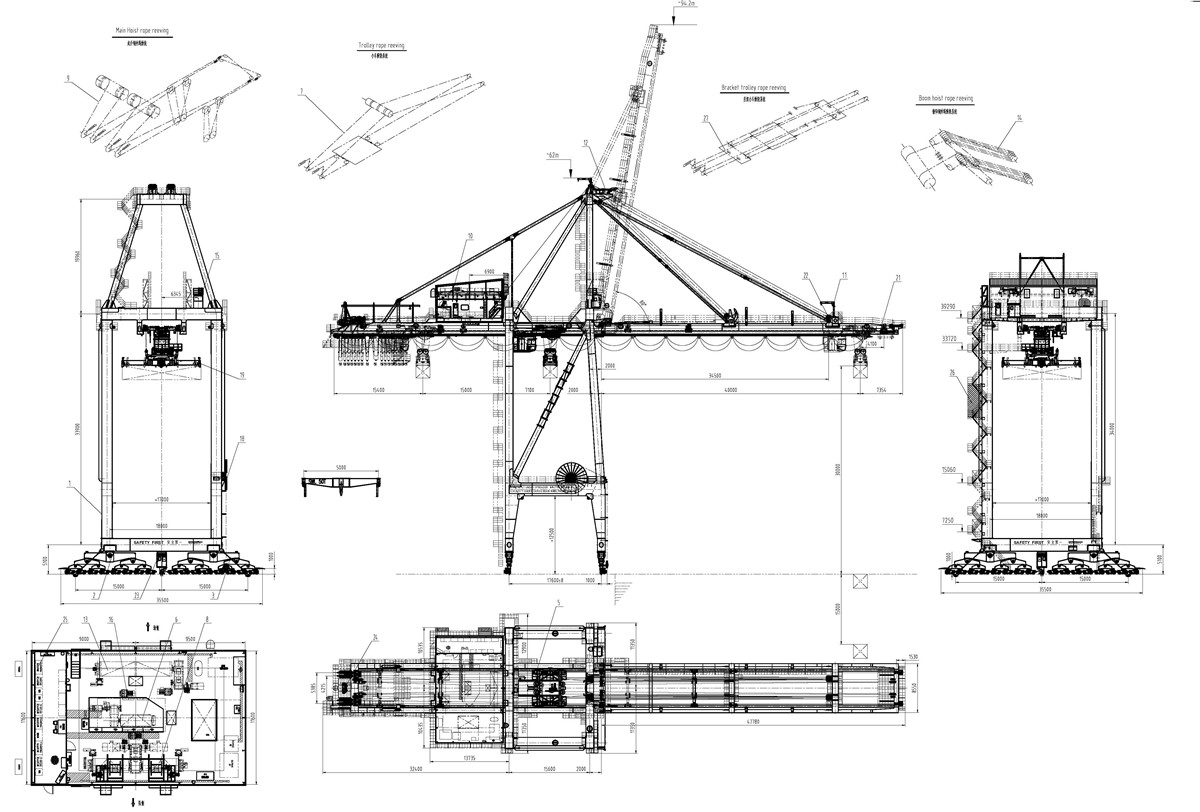

The crane management system shall be full computerised operation, complete with sensors and transducers which shall be installed permanently on each crane and work in conjunction with the plc. provide with the monitor to monitoring diagnostics of crane, telling the data collection on the crane’s operating system, operated jointly with the device at least including the electrical power supply device, motor controls, operator control, motor, gear reducers and etc., such programme shall be flexible enough to change or modify by the operator at later stage. Having following function. 1.Condition Monitoring 2.Fault Diagnosis 3.Store the record and display system of the STS 4.Preventive maintenanceOutline Drawing

Technical Parameter Table

| Capacity of spreader | T | 30.5 | 35 | 40.5 | 50 | |||

| Capacity of Hook | T | 38 | 45 | 50 | 60 | |||

| Working duty | A7 | A7 | A8 | A8 | ||||

| Span | m | 10.5 | 10.5 | 22 | 22 | |||

| Out reach | mm | 38000 | 30000 | 38000 | 55000 | |||

| Backreach | mm | 10000 | 10000 | 11000 | 18000 | |||

| Base distance | mm | 16.5 | 17.63 | 16 | 16 | |||

| Gantry frame height | mm | 75670 | 68100 | 8000 | 9500 | |||

| Lifting height | Above Rail | m | 22 | 22 | 28 | 38 | ||

| Below Rail | m | 16 | 10 | 14 | 14 | |||

| Speed | Hoisting | With full load | m/min | 46 | 30 | 50 | 70 | |

| Only with spreader | 120 | 60 | 120 | 150 | ||||

| Trolley travelling | 150 | 120 | 120 | 220 | ||||

| Crane traveling | 45 | 25 | 45 | 45 | ||||

| Boom hoisting time, one way | min | 7 | 6 | 5 | 5 | |||

| Total power | KW | 650 | 500 | 920 | 1700 | |||

| Max. working load of wheel | KN | 300 | 260 | 400 | 450 | |||

| Crane rail | P50 | P50 | QU80 | QU100 | ||||

| Power supply | 380V,50HZ,3 Phase AC or 10KV,50Hz,3Ph | |||||||