Description

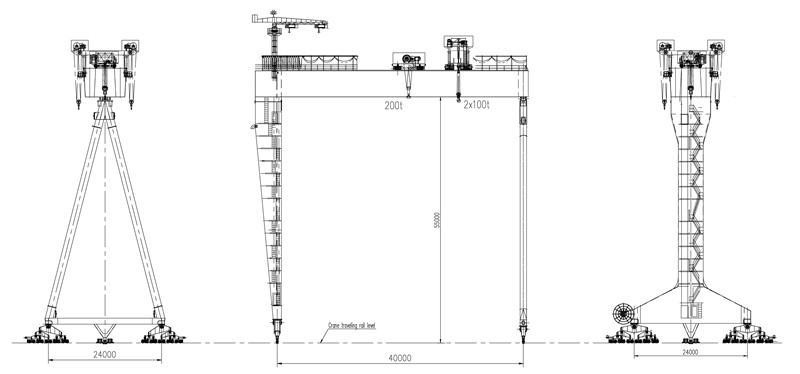

With the development of large-scale shipbuilding, shipbuilding gantry crane is the rapid growth of demand. Compared with the traditional portal crane, large shipbuilding gantry crane has the obvious advantage of the installation and transportation and turn over of hull sections during ship building. It spans the dock (berth), can provide on-site assembly service at the coverage plane in the dock, not only has the lifting, horizontal transport function, but also can implement hull air turnover, adjusting the fragment to the welding position of ship required. Shipbuilding gantry steel metal structure part mainly contains the main beam, rigid legs, flexible legs, ground beam ,railing, cab,hoist trolley etc. Crane main beam adopts double beam structure, on the panel of the two main beam, there are 4 rails which is used for trolley traveling. One set crane has two main hook, running on a track on the bridge flange, in order to turn and lifting large hull blocks. In order to light the dead weight, rigid legs adopt box type; flexible legs adopt herringbone frame structure, composed by the joint, two pipes, under the joint. Crane power supply adopt cable drum. Trolley adopt suspension cable pulley device, set on the top surface of the two main beams.Technical Parameter Table

| Shipbuilding Gantry Crane Main Specification | |||||||

| Lifting capacity | 2x25t+100t | 2x75t+100t | 2x100t+160t | 2x150t+200t | 2x400t+400t | ||

| Total Lifting capacity | t | 150 | 200 | 300 | 500 | 1000 | |

| Turning over capacity | t | 100 | 150 | 200 | 300 | 800 | |

| Span | m | 50 | 70 | 38.5 | 175 | 185 | |

| Lifting Height | Above rail | 35 | 50 | 28 | 65/10 | 76/13 | |

| Below rail | 35 | 50 | 28 | 65/10 | 76/13 | ||

| Max. Wheel load | KN | 260 | 320 | 330 | 700 | 750 | |

| Total power | Kw | 400 | 530 | 650 | 1550 | 1500 | |

| Span | m | 40~180 | |||||

| Lifting Height | m | 25~60 | |||||

| Working duty | A5 | ||||||

| Power source | 3-Phase AC 380V50Hz or as required | ||||||

Product Features

1.It have multiple functions of single hanging, hoisting, turnover in the air, slight horizontal turnover in the air and so on; 2.The gantry falls into two categories: single girder and double girder. To rationally utilize materials, the girder adopts optimum design of variable section; 3.The gantry rigid legs with a single column and double column type for customer choice. 4. Both the upper trolley and the lower trolley can cross each other for operation; 5. All the lifting mechanism and travelling mechanism adopts frequency conversion speed regulating; 6. On the top of the girder at the side of rigid leg is equipped a jib crane to accomplish maintenance of upper and lower trolley; 7.In order to prevent the storm attack, such safe and reliable anti-wind devices as rail clamp and ground anchor are equipped.Painting

The shipbuilding gantry crane shall use the zinc epoxy painting system. They paint could guarantee a minimum paint life of minimum 5 years against cracks, rusty, peeling and discolourtion. Every surface of metal have surface cleaning according to standard sis st3 or sa2.5. Then they are painted with one coat of epoxy zinc rich primer with dry film thickness of 15 microns. The primer coat - shall be painted with one coat epoxy zinc rich primer, dry film thickness of 70 microns. The intermediate paint shall be painted with one coat epoxy micaceous iron oxide, dry film thickness of 100 microns.The finish coat shall be painted with two coats, poly urethane, the thickness of each coat is 50 microns.The total dry film thickness shall be not less than 285 microns.Crane Management System (CMS)

The crane management system shall be full computerised operation, complete with sensors and transducers which shall be installed permanently on each crane and work in conjunction with the plc. provide with the monitor to monitoring diagnostics of crane, telling the data collection on the crane’s operating system, operated jointly with the device at least including the electrical power supply device, motor controls, operator control, motor, gear reducers and etc., such programme shall be flexible enough to change or modify by the operator at later stage. Having following function. 1.Condition Monitoring 2.Fault Diagnosis 3.Store the record and display system Preventive maintenanceOutline Drawing